We are committed to reflect changing customer needs and transformation of mobility. As being a rapidly growing and interesting market, we also take part in EV revolution, producing various components for BEV and PHEV battery systems. Our machine range and self-developed production automation system allow us to easily react on changing demands and design evolution. Our production lines are capable to produce parts for more than 3.5M battery modules in a year.

Our battery module covers for small to medium volume projects are made of V0 grade PC/ABS. These thin wall parts require precise process control to maintain required product quality.

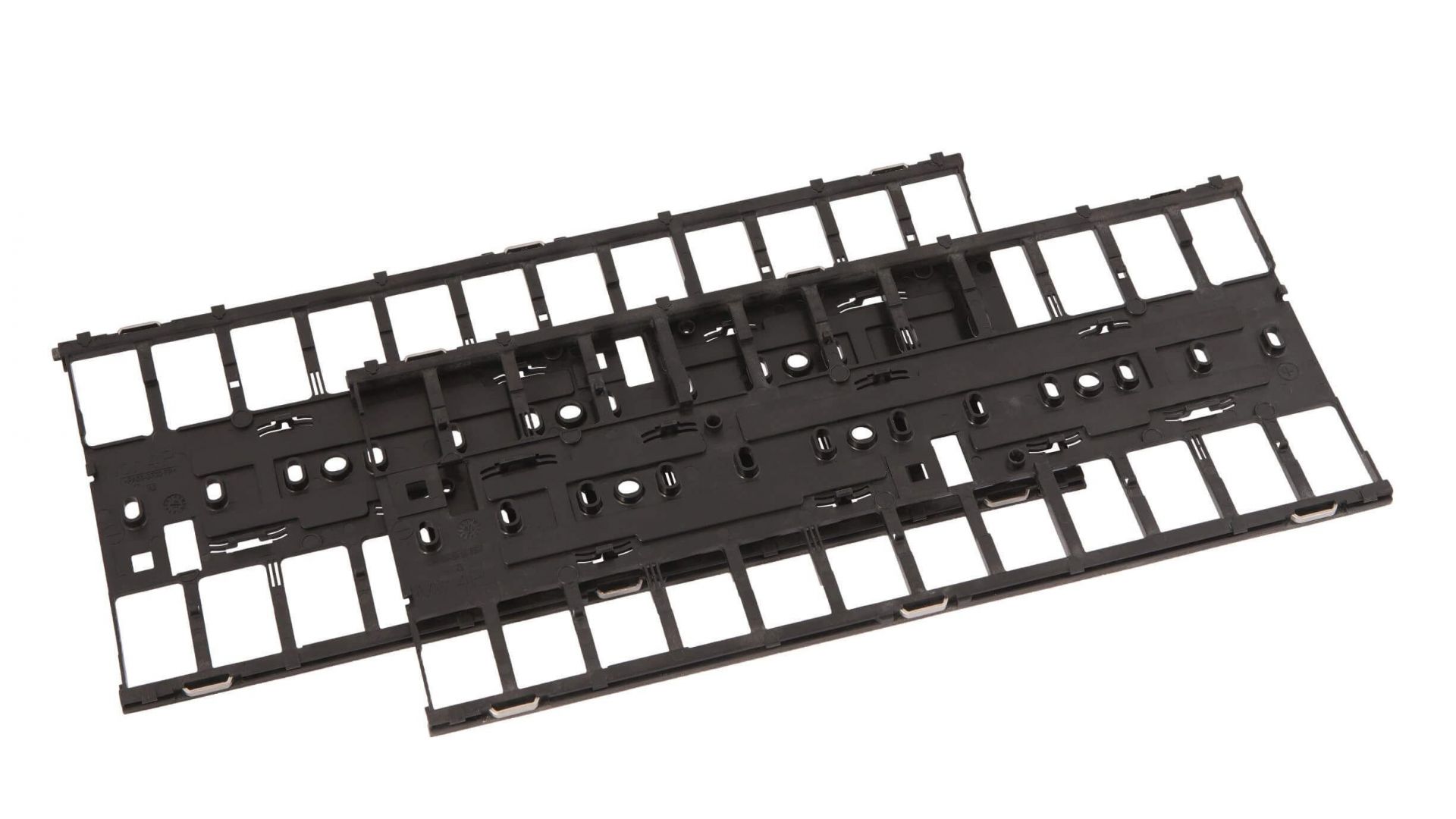

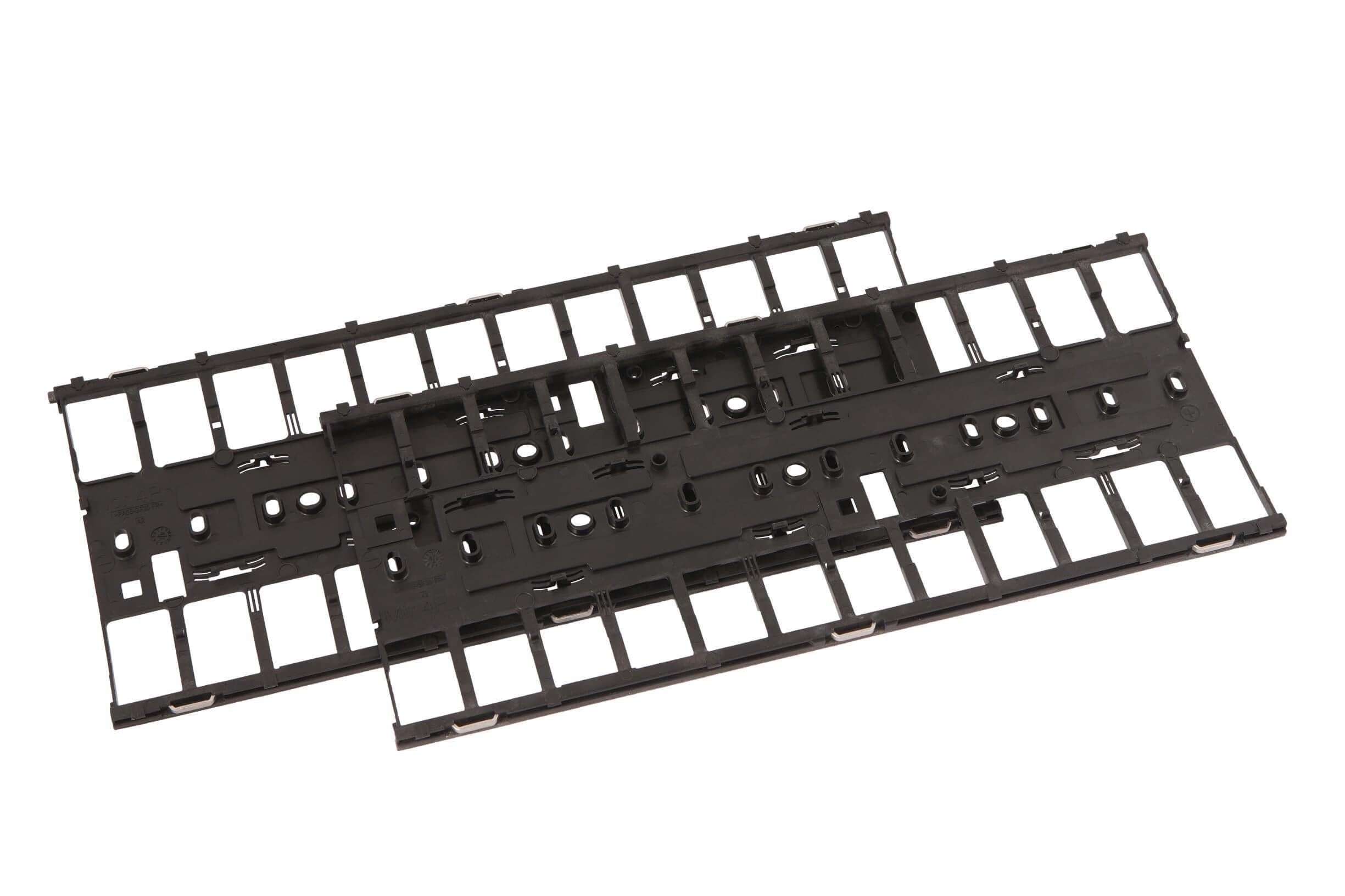

We produce insert-molded holders for battery cell’s busbars. Products have tight flatness requirements and can include 6 to 23 metal inserts. We produce the most complex parts on vertical injection molding machine having a built in camera control system to facilitate insert feeding and ensure product quality. We inject the parts from V0 grade, glass fiber filled polyamide.

Similar to holders, our end plates are also over-molded components. Different size and orientation of the metal inserts require sophisticated feeding and robot system to maintain high runner production. We inject the parts from V0 grade, glass fiber filled polyamide.